Charcoal carbonization retort kiln sawdust charcoal furnace coffee husk wood charcoal making machine

KUNTENG New type Charcoal carbonization retort kiln inside temperature can reach to 800 ℃,the output charcoal with high quality, high calorific value and less impurities.Continuous Charcoal carbonization retort kiln realize continuous production of charcoal and solves the problem of slow and less production by other charcoal making machine.

Charcoal carbonization retort kiln sawdust charcoal furnace coffee husk wood charcoal making machine

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuous Charcoal carbonization retort kiln can be customized in size.

|

Charcoal carbonization retort kiln sawdust charcoal furnace coffee husk wood charcoal making machine workflow

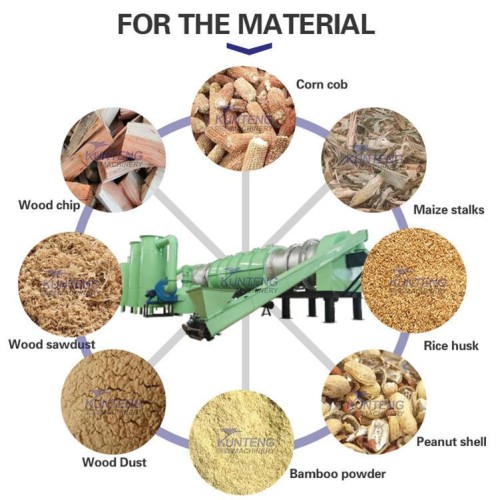

Wood scraps, coconut shell, corn sticks,bamboo scraps,etc, are crushed by shredder machine---Rotary dryer drying sawdust (if the moisture ≤12% does not need to be dried), --- carbonized by Continuous Charcoal carbonization retort kiln, --- Produced charcoal can be used for lithium ion battery electrode materials,or for fuel --- Charcoal briquette machine to make hookah charcoal,barbecue charcoal.

All agricultural waste and household waste can be carbonized by our Charcoal carbonization retort kiln sawdust charcoal furnace coffee husk wood charcoal making machine.

CHARCOAL MAKING RELATED PRODUCTS

Charcoal ball press machine

Charcoal briquette machine

Batch charcoal carbonization furnace

CUSTOMER INSTALLATION SITE

Malaysia customer Charcoal carbonization retort kiln charcoal making machine installation site.

Romania customer Charcoal carbonization retort kiln charcoal making machine.

Our domestic customer Charcoal carbonization retort kiln charcoal making machine installation site.

Vietnam customer Charcoal carbonization retort kiln charcoal making machine installation site.

Our service

KUNTENG is a professional manufacturer of Charcoal carbonization retort kiln charcoal making machine.we have more than 20 years of rich experience of design and produce whole charcoal making production line,We provide customers with one-stop services from design,production, shipping,installation,and training how to operate,please feel free to tell us your requirement.

Pre-sale

1. According to your needs, select right model for you.

2. According to your special requirements, design customized solution and manufacture customized products for you.

3. Welcome your visit.

Sale

1. Sign contract, pay deposit, we arrange production.

2. Product acceptance.

3. Help you formulate construction scheme.

After-sale

1. Assign engineer service for you on-site freely.

2. Install and adjust device, train how to operate.

3. After installation, leaving 1-2 technical staff to help you on-site production, until achieve customer satisfaction.

Kunteng Machinery founded in 1999, located in Zhengzhou Henan province, China.mainly focuses on design and manufacturing charcoal making machine, charcoal carbonization furnace, charcoal retort kiln, charcoal briquette machine,hot air dryer machines, waste sorting machines, coconut shell processing machines. Our machine has passed ISO9001:2000 CCC,CE certification.and has already spread over the world.

Q: What is your Business Model? Trading company or factory?

A:We are a 25 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: Can I visit your factory?

A: Yes.Many domestic and international customers visit our factory every month. Our company is located in Zhengzhou Henan province,China, you can come here by air or train. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO. We will pick you up at airport. Welcome to visit our factory.

Q: What is the Installation of your products?

A: KUNTENG Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians round way air tickets, food and lodging, most importantly to guarantee the technicians safety.

Q: What should I provide to get the suitable quotation? A: 1.What is your raw material? 2. What is the capacity per hour you required? 3. What is the final product use?

Once we get your answers,we can provide you the best quotation immediately.

|

Products

|

Products  Continuous carbonization furnace

Continuous carbonization furnace

Continuous sawdust carbonization furnace coconut shell palm shell carbonization equipment rotary carbonization furnace

Continuous sawdust carbonization furnace coconut shell palm shell carbonization equipment rotary carbonization furnace