Q: What is your Business Model? Trading company or factory?

A: We are a 15 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou Henan province, China, you can come here by air or train. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO. We will pick you up at airport. Welcome to visit our factory.

Q: What is the Quality of your products?

A: KUNTENG Group products come with best quality, and our products passed CE certification, exported to lots countries around the world, such as Australia, Malaysia, India, Italy ,Indonesia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What is the Installation of your products?

A: KUNTENG Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians round way air tickets, food and lodging, most importantly to guarantee the technicians safety.

Q: How long is the Warranty of your equipment?

A: Our warranty period is one year generally.

Q: What should I provide to get the suitable quotation?

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product?

You can send inquiries from this page.Once we get your answers,we can provide you the best quotation immediately.

Plez feel free to contact us for details.

|

Products

|

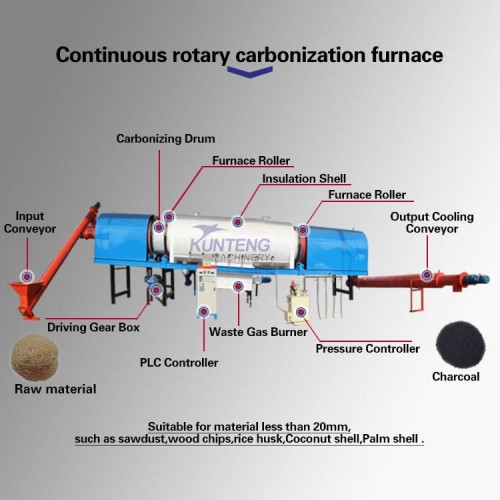

Products  Continuous carbonization furnace

Continuous carbonization furnace

Environmental Wood Carbonization Stove Charcoal Making Furnace

Environmental Wood Carbonization Stove Charcoal Making Furnace