|

Products

|

Products  charcoal briquette machine

charcoal briquette machine

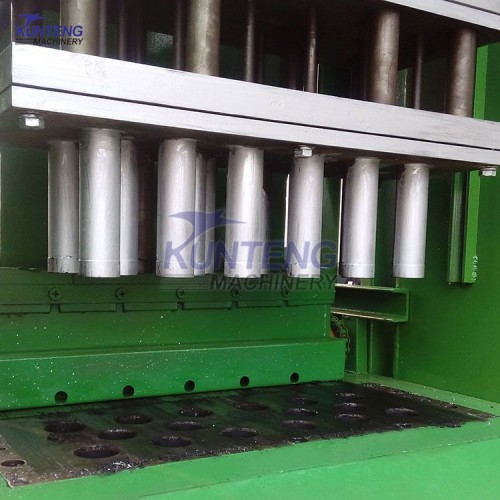

Shisha Coal Briquette Machine Coffee Grounds Charcoal Forming Machine Shisha Charcoal Forming Machine

Shisha Coal Briquette Machine Coffee Grounds Charcoal Forming Machine Shisha Charcoal Forming Machine