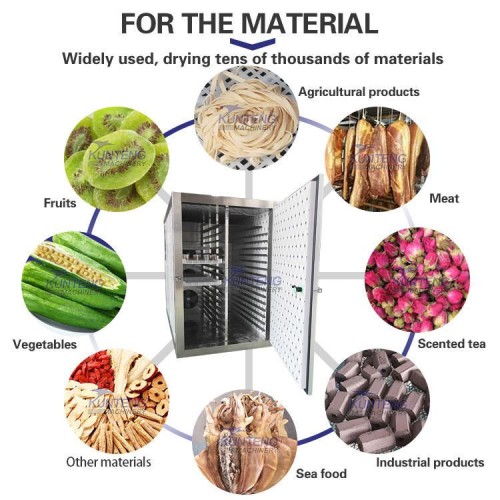

Fruit:Almonds, jujube, peanuts, longans, walnut, papaya tablets, apple, lemon, hawthorn pills, bananas, etc. Vegetable:Asparagus, beans, kidney beans, lentils, eggplant, red pepper, Chinese prickly ash, black fungus, tremella, papaya tablets, pills, bitter melon, radish, cucumber slices, mushrooms, mushrooms, ginger, garlic, green onions,Onion,Sweet potato, Pumpkin,etc. Chinese herbal remedy:Flos lonicerae, radix scutellariae, salvia miltiorrhiza, burdock, fructus schisandrae, codonopsis, radix rehmanniae, prepared rhizome of rehmannia, mulberries, forsythia, Chinese wolfberry, etc. Others:Lily, rose, peony seed,fennel seeds,etc.

|

Products

|

Products  dryer machine

dryer machine

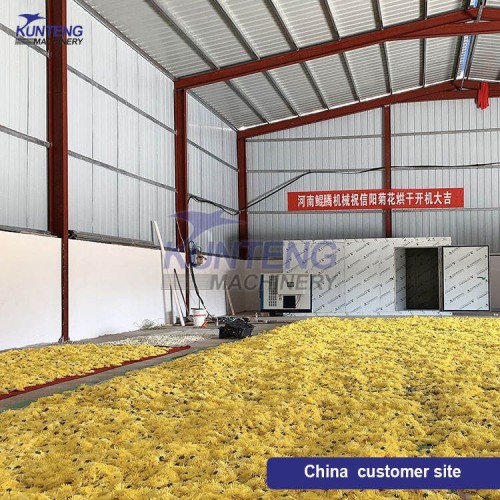

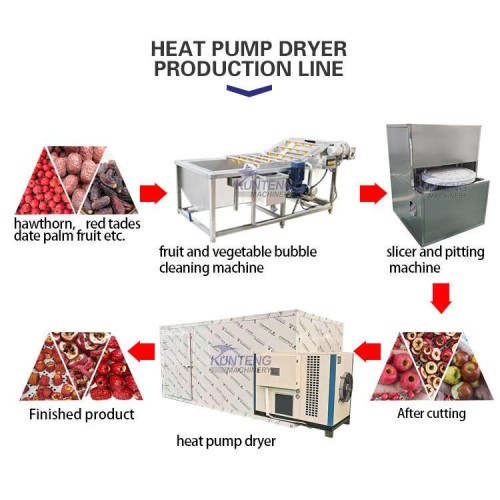

Multifunctional Fruit&Vegetable Heat Pump Dryer Ginseng Slices Drying Oven Dryer Machine Flower Tea Hot air Dryer

Multifunctional Fruit&Vegetable Heat Pump Dryer Ginseng Slices Drying Oven Dryer Machine Flower Tea Hot air Dryer