|

Products

|

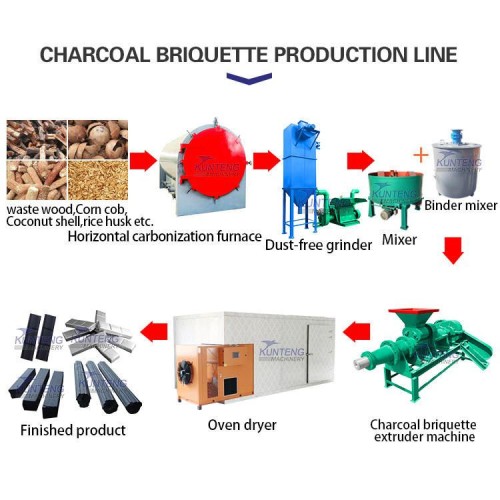

Products  charcoal briquette machine

charcoal briquette machine

High Quality Biochar Processing Machine Charcoal Powder Briquettes Making Machine Coal Extruder Machine

High Quality Biochar Processing Machine Charcoal Powder Briquettes Making Machine Coal Extruder Machine