The coal powder briquette making machine making process could follow these steps: Feeding-- crushing---- mixing------ ball pressing------ drying------final product.

|

Products

|

Products  Ball Press Machine

Ball Press Machine

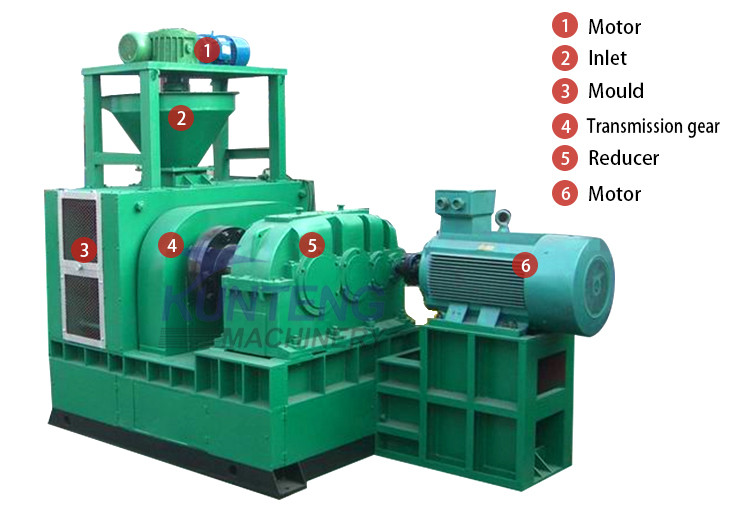

High Pressure Hydraulic Forcing Input Dry Mineral Powder Ball Shape Briquetting Machine Coal coke Press Machine

High Pressure Hydraulic Forcing Input Dry Mineral Powder Ball Shape Briquetting Machine Coal coke Press Machine