Q1. May I visit your company?

Warmly welcome you to visit our factory, consultation, sample testing, please contact us before making an appointment.

Q2. How much is the delivery charge?

It depends on your import port and the number of machines, different sizes, different quantities, different port shipping costs.

Q3. How to install and operate machine?

We will provide the installation and operation manual, you can follow the manual for installation and operation, can also provide you with video or online support.

If you are interested in our products, please feel free to contact with us for details.

|

Products

|

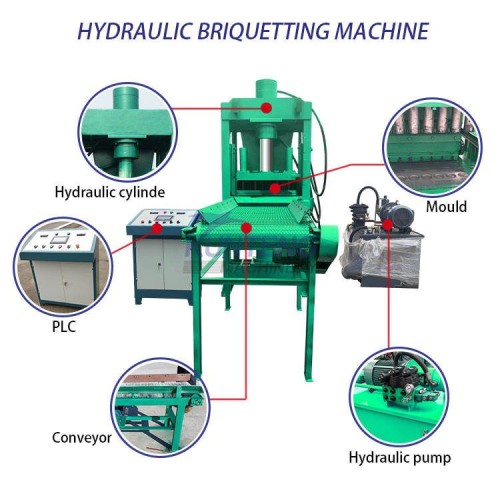

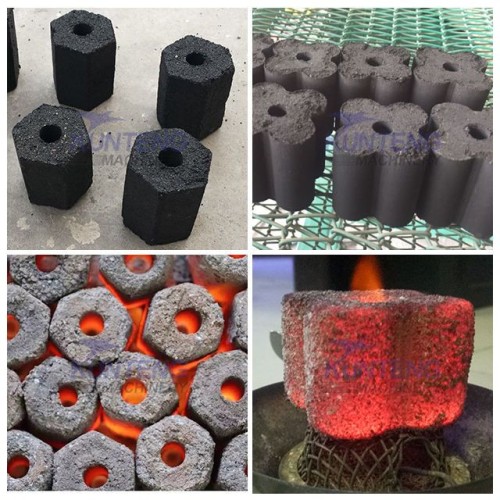

Products  charcoal briquette machine

charcoal briquette machine

Coconut Charcoal Hydraulic Press Machines Sawdust Charcoal Briquette Machines Biomass Charcoal Briquette Machine

Coconut Charcoal Hydraulic Press Machines Sawdust Charcoal Briquette Machines Biomass Charcoal Briquette Machine