Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer in China, passed Alibaba field certification.

Q2: May I know more about the briquette making machine?

A2: Your requirements in details will help us a lot for the information of the briquette making machine. Such as the raw material, the input capacity, the power supply, etc.

Q3: What is the binders used in the briquetting process?

A3: It depends on the properties of the raw material, and also the usage of briquettes. We will provide you with guidance and help.

Q4: How long is the warranty period?

A4: Normally 12 months. Except for wearing parts.

Q5: What’s your delivery time??

A5: We will arrange for shipping in factory within 10 working days after receiving the advance payment. When there are briquette machines in stock, it will be shorter.

|

Products

|

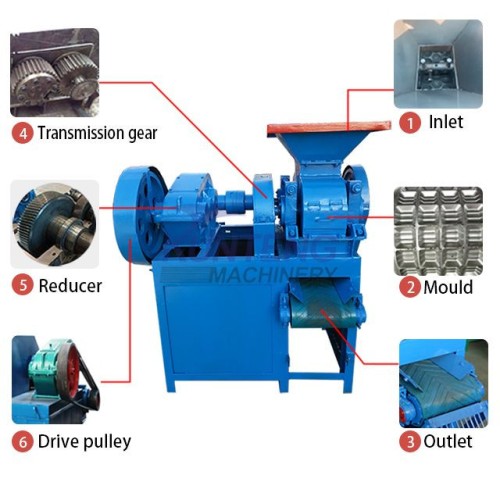

Products  Ball Press Machine

Ball Press Machine

Coal powder ball pressing machine automatic coal powder forming machine barbecue charcoal block pressing machine

Coal powder ball pressing machine automatic coal powder forming machine barbecue charcoal block pressing machine