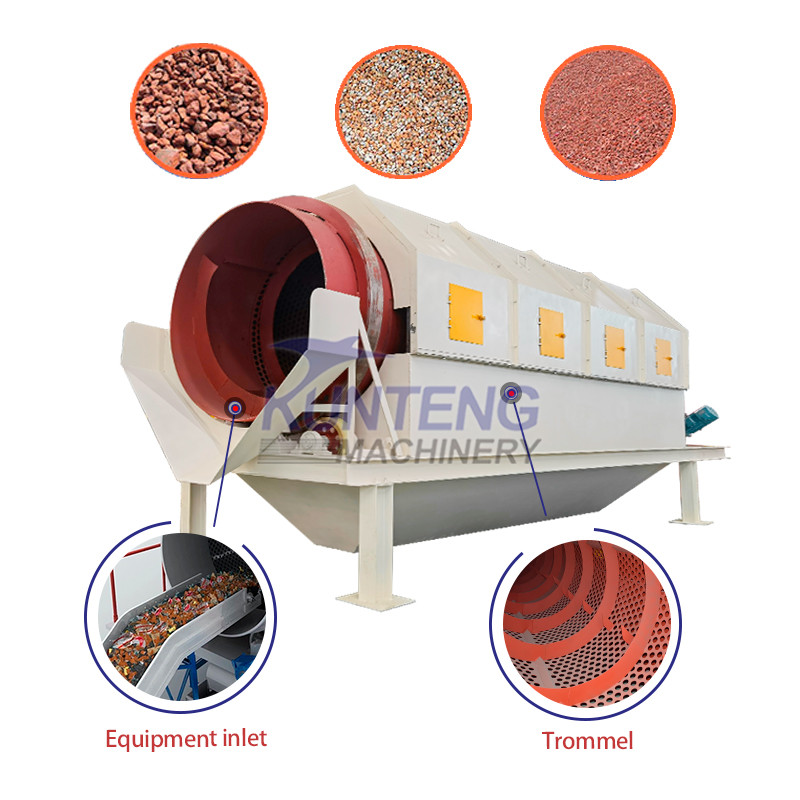

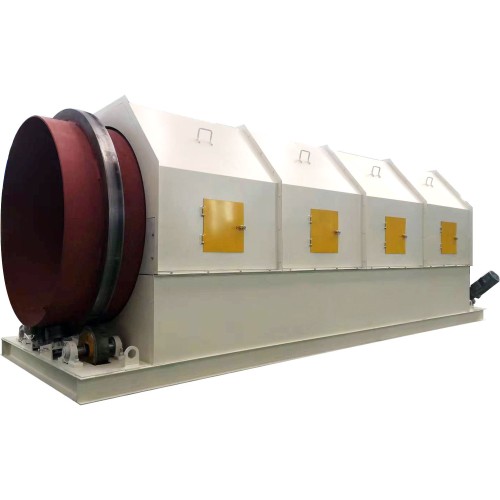

Kunteng Machinery founded in 1999, mainly focuses on design and manufacturing waste sorting machines. include trommel screen machine, air separation machine, magnetic separators, garbage bag breaking machine, waste shredder machine, manual sorting tables, waste baling machine, chain plate feeder, belt conveyor.etc. Kunteng Machinery is a high-tech modern enterprise integrating scientific research and development, production and sales, engineering design, installation services. Our machine has passed ISO9001:2000 CCC,CE certification.Our machines has already spread over the world.We can provide customers with one-stop service and solutions, complete equipment, on-site installation, and after-sales support.