ADVANTAGES

|

Products

|

Products  Ball Press Machine

Ball Press Machine

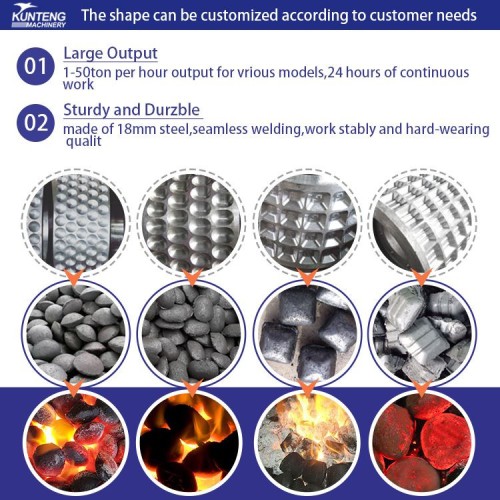

Carbon powder ball pressing machine carbon block forming equipment automatic smokeless carbon manufacturing machine

Carbon powder ball pressing machine carbon block forming equipment automatic smokeless carbon manufacturing machine