2) Design and manufacture products according to your requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer.

Services during the sale:

1)Take photos(including raw material, semi-products, final products, and loading products)

2) Pre-check and accept products ahead of delivery.

3) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services:

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace to every customer.

3) Install and debug the equipment, ensure the drying running smoothly.

4) Examine the equipment regularly.

|

Products

|

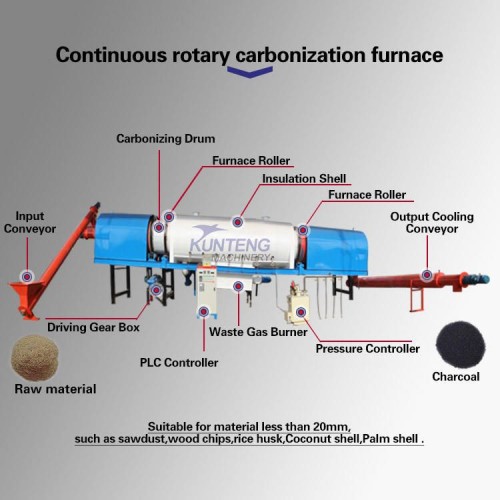

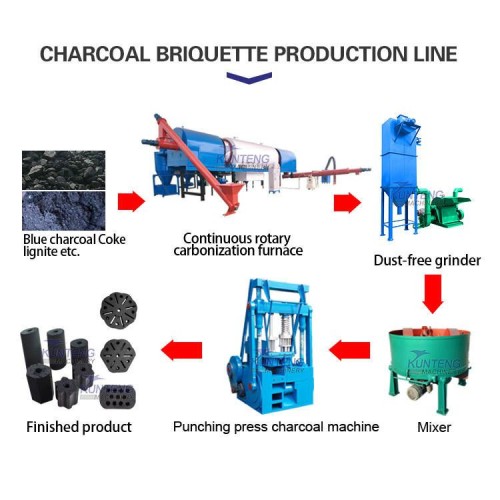

Products  Horizontal carbonization furnace

Horizontal carbonization furnace

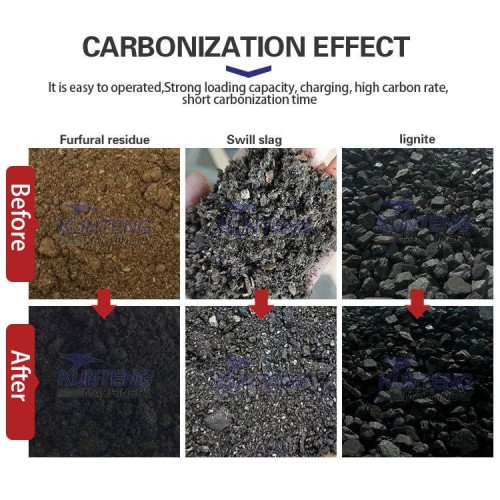

Big Capacity Continuous Carbonization Furnace Biochar Making Machine Coconut Charcoal Sawdust Charcoal Making Machine

Big Capacity Continuous Carbonization Furnace Biochar Making Machine Coconut Charcoal Sawdust Charcoal Making Machine