|

Products

|

Products  charcoal briquette machine

charcoal briquette machine

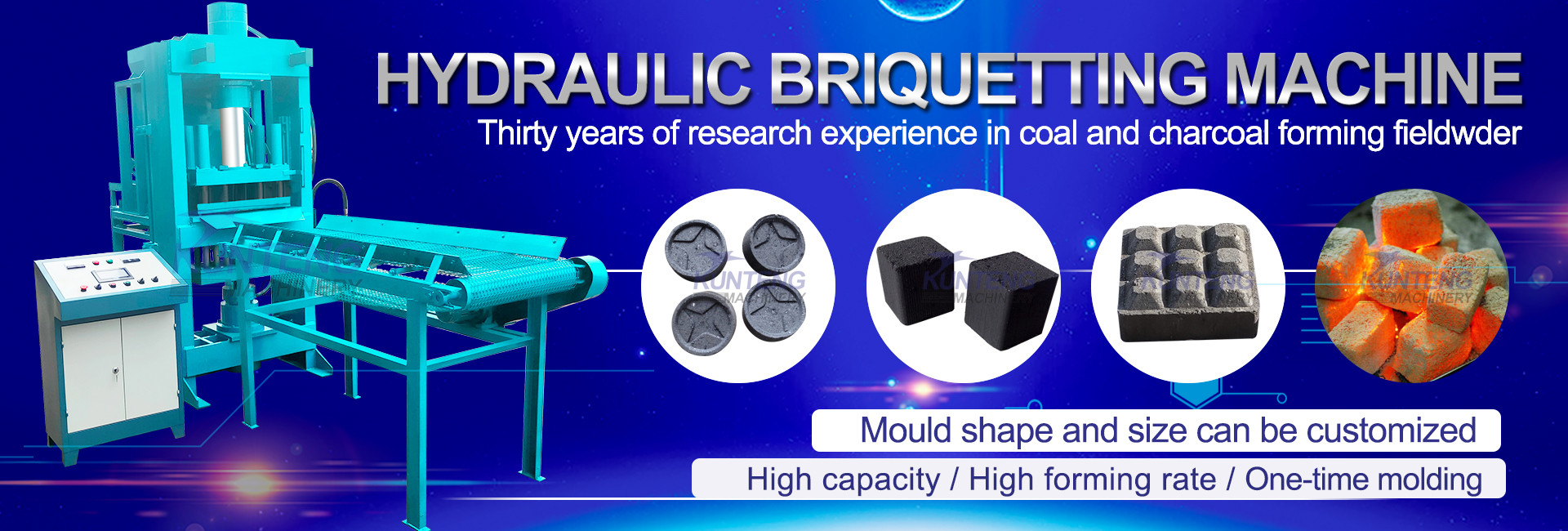

Automatic Hydraulic Charcoal Briquette Equipment Powder Material Forming Machine

Automatic Hydraulic Charcoal Briquette Equipment Powder Material Forming Machine

Automatic Hydraulic Charcoal Briquette Equipment Powder Material Forming Machine

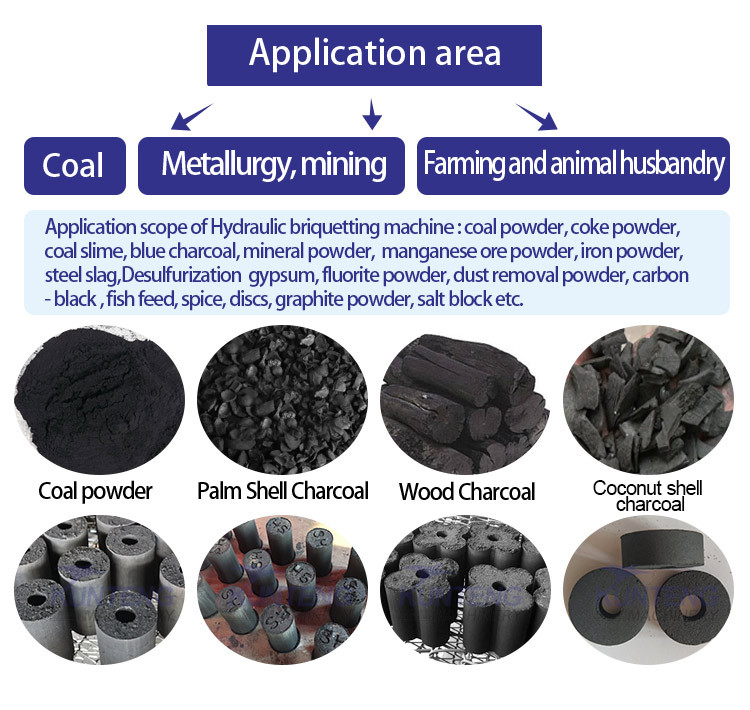

Hydraulic press machine used to press various powder material into shapes,like charcoal,coke,coal,mineral,etc.Mold shape and size can be customized like round ,cubic,cylinder,etc.

It is consist of main machine,hydraulic station,PLC,output conveyor.

Hydraulic system low maintenance rate,high forming rate,excellent performance,main used in briquette making,pharmaceutcal,chemical field,etc.

It has high pressure,less wearing parts,low noisy advantages.

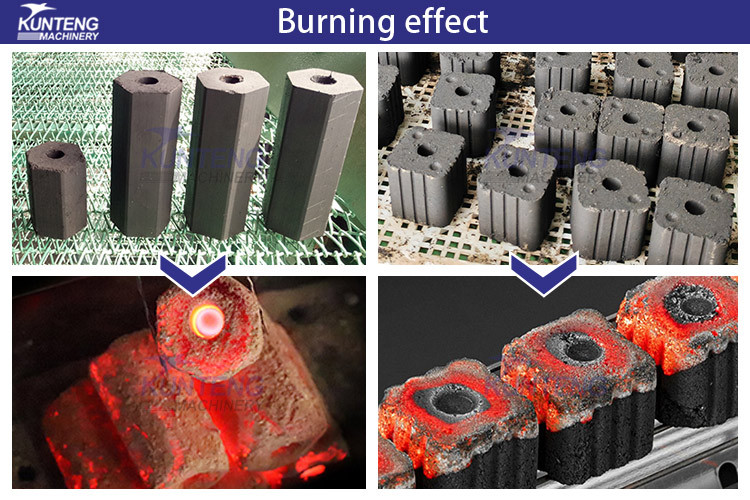

1.Full combustion

2.Smokeless and tasteless

3.Automatic ash remova

The Main Date of Hydraulic Charcoal Shisha Briquette Press Machine,there are two models for your reference:(the below output capacity takes coal powder as an example)

| No. | Model | Capacity(KG/H) | Machine Size(MM) | Weight (KG) |

| 1 | KT100 | 300 | 3100*1100*2100 | 2000 |

| 2 | KT200 | 1000 | 3100*1100*2600 | 3200 |

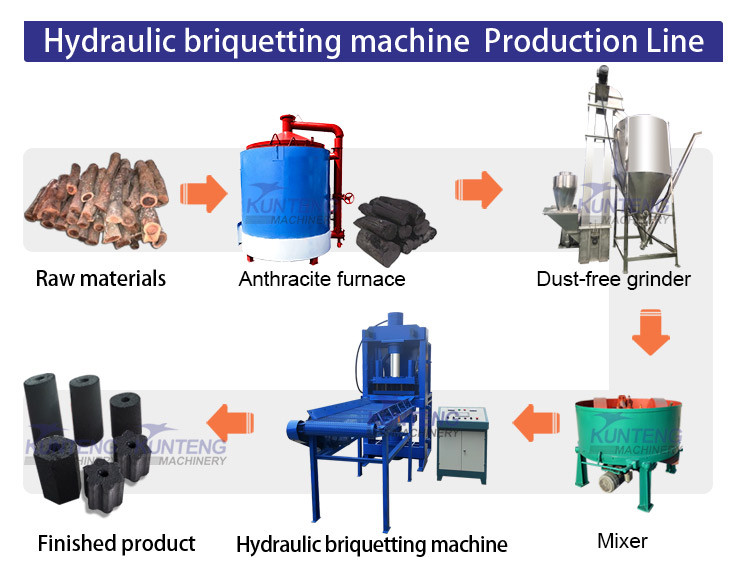

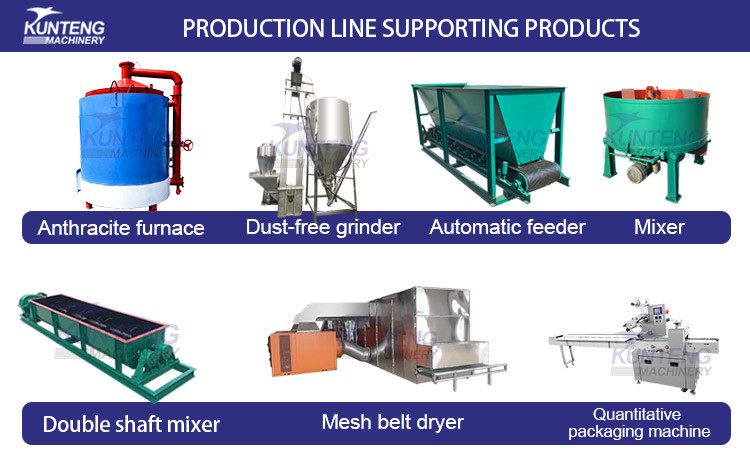

We can also provide the whole production line for you.If your raw material is big wood,such as tree branch,coconut husk,bamboo,ect.,you can refer to the below production line:charcoal furnace-Dust free grinder-Mixer-charcoal briquette making machine-BBQ charcoal/Shisha charcoal/Cooking Charcoal.

This is our customers site in many other countries.

Customer visit our factory and test the charcoal briquette production line:

The machines for whole production line will be loaded into the 20/40 GP container directly.

1.Founded in 1999, KUNTENG Machinery is a technology-based enterprise integrating R&D, manufacturing, sales and after-sales.

2.We have our own R&D(research and development)team. We have ability design the factory building, circuit direction, and machine assemble for the entire project.

3.Wood Charcoal Briquitte Machine is strictly controlled by the quality inspection department before loading to the container to ensure that each set of equipment work smoothly.

4.The companys products have passed more than 100 national patents, and passed passed ISO, CE quality system certification.

Our service:

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipment;

3) Training the first-line operators on site;

4) Examining the equipment regularly;

5) Taking the initiatives to eliminate the failure(s) rapidly at site;

6) Distributing the guarantee fittings door-to-door;

7) Providing technical exchanging;

8) Providing maintenance for big items.

FAQ:

1.How many days do you need to produce this machine?

This is specially designed machine according to your specific requirement. From engineer designing

to production completion, It needs about 20-30 days.

2. What does your factory do regarding quality control?

We pay much more importance to quality control from the very begining to the end of production. Every

machine will be fully assembled and carefully tested before shipment.

3. Whats your machine quality guarantee?

Quality guarantee time is one year, we choose world famous brand components to keep our machine in

perfect working condition.

4. Are you able to give installation and commissioning overseas? How long will it take?

Yes, we supply overseas service, but customer needs to pay for the engineers flight tickets and hotel

foods.Small machine usually takes within 5 days.Big machine usually takes about 20 days.